Work and Labor Environment

At the Fukushima Daiichi Nuclear Power Station, we are working to mitigate risks, including those from radioactive materials, giving highest priority to ensuring the safety of people in the local communities, workers and employees, and the surrounding environment. Through ongoing sampling of the site and the ocean, we monitor the impacts. We are also seeking to improve the labor environment, toward accelerating the decommissioning work and building greater trust.

The Working Environment at the Fukushima Daiichi Nuclear Power Station

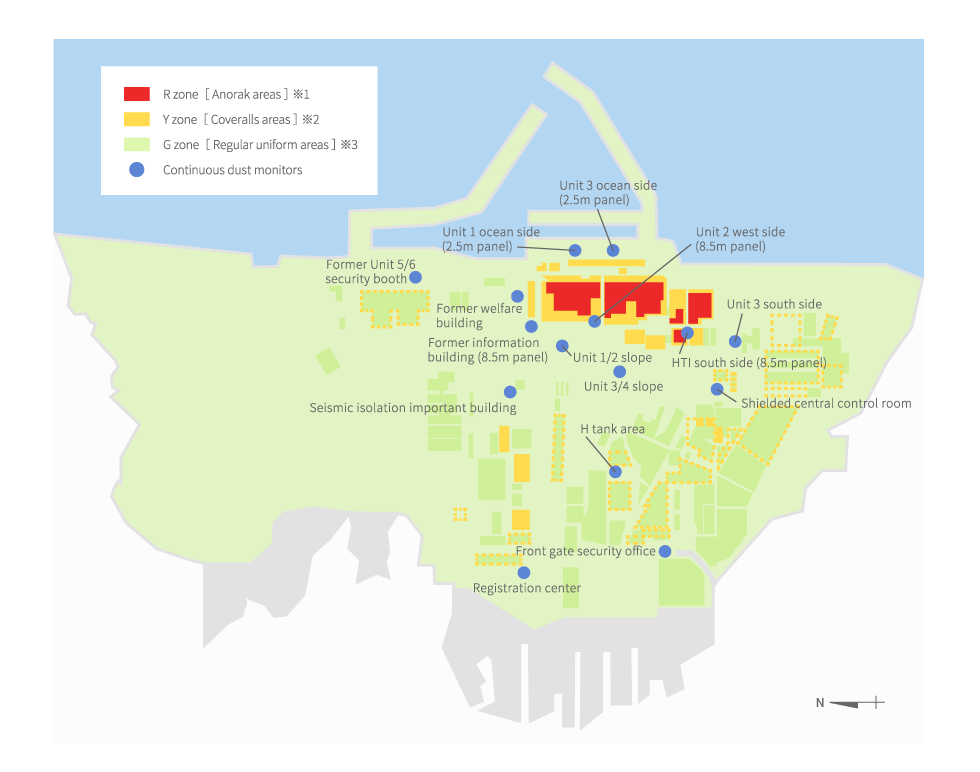

At the Fukushima Daiichi Nuclear Power Station, there are standards for wearing of protective clothing, masks, and other items based on the nature of the work and the work area. As radioactive material concentration is reduced such as by decontamination and paving over the ground, and in other ways the standards are met, regular clothing areas are being gradually expanded, to reduce the physical burden on workers and improve their working efficiency. At the time of the accident, wearing of protective clothing and full-face masks was necessary throughout the entire site; but today, on 96 percent of the site area, work is possible wearing regular uniforms and dusk masks.

Control zone layout (as of May 2018)

*1 In the Unit 1 to 3 reactor buildings, the Unit 1-4 turbine buildings, and the surrounding buildings, areas with retained water.

*2 The Y zone designation shown by the yellow dotted lines applies to work involving contamination, such as handling of high-concentration saltwater. For work such as patrols or site surveys for work planning, the G zone standard applies.

The Y zone standard is set temporarily even outside the Y zone areas shown in the figure, in G zone areas when work is performed involving high concentration particulate matter (building demolition, etc.) or on tank transfer lines for high concentration saltwater, etc.

*3 In addition to the G zone areas shown in the figure, covers some other areas such as the second and third floors of the common pool building.

Clothing in each zone

| R zone [Anorak areas] |

Y zone [Coveralls areas] |

G zone [Regular uniform areas] |

|---|---|---|

|

Full-face mask  |

Full-face mask or half-face mask   |

Disposable dusk mask  |

|

Anorak worn over coveralls  |

Coveralls  |

Regular uniform  |

*1 For indoor work that includes water treatment equipment (Multi-nuclide Removal Facility (ALPS), etc.) (other than inspection, etc.), a full-face mask is to be worn.

*2 For work in areas with tanks containing high-concentration saltwater or Sr treated water (not including work that does not involve handling the high-concentration saltwater, etc., patrols, site surveys for work planning, inspections, etc.) and work involving tank transfer lines, a full-face mask is to be worn.

The Labor Environment at the Fukushima Daiichi Nuclear Power Station

-

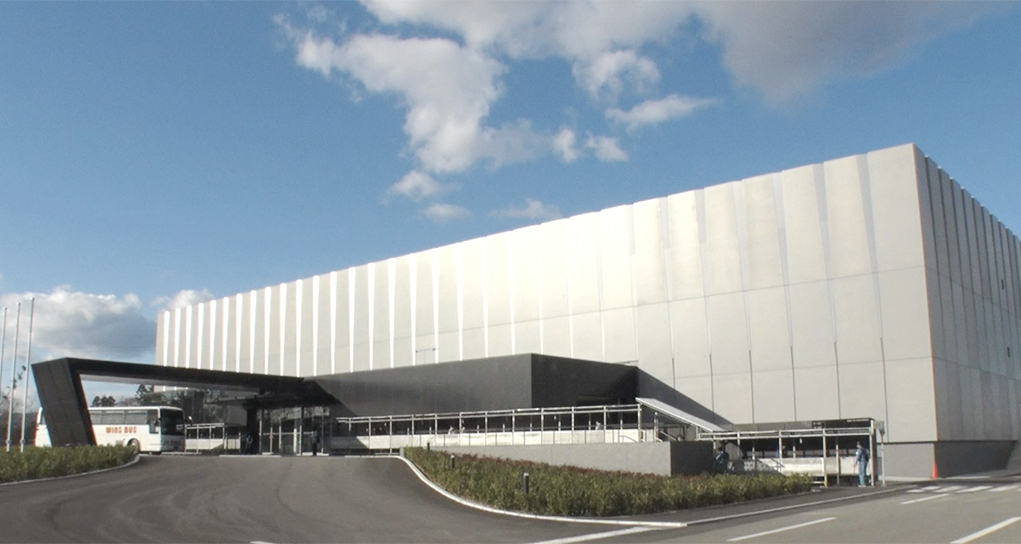

Large break room

In May 2015, a large break room was completed, enabling resting and meetings in a relaxing atmosphere. In the eating area, hot foods can be enjoyed; and a convenience store and shower room are also available.

-

New administrative building and partner company wing

In October 2016, work in the new administrative building began, enabling office tasks to be performed in a more relaxing environment. Right next to the administrative building is a wing housing partner companies. As office duties can now be carried on in close proximity, a framework for close cooperation has been created on the site.

-

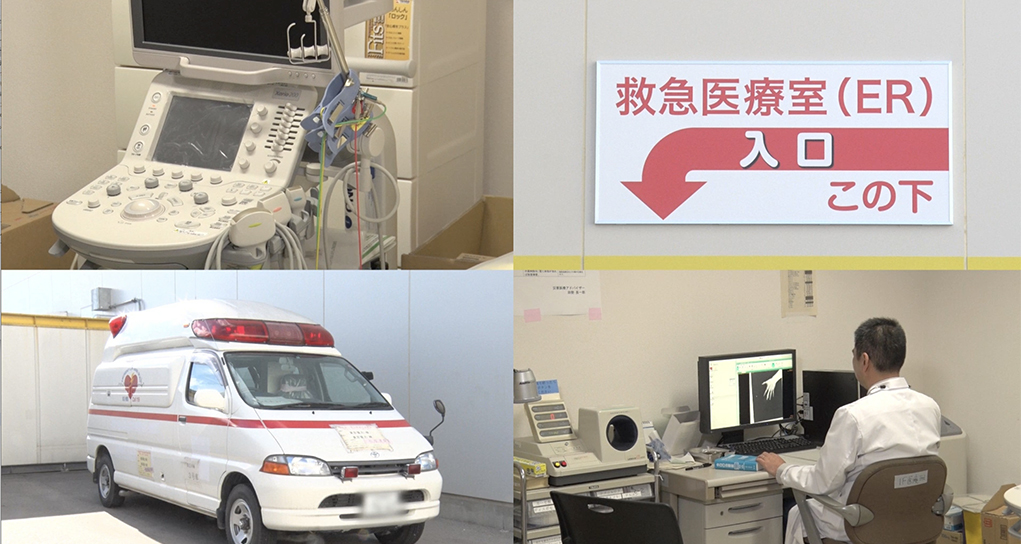

Emergency medical care readiness

To help ensure safety in the event of an accident, 24-hour emergency medical care is available in the facility for controlling entry to the work sites at the Fukushima Daiichi Nuclear Power Station. A heliport is also provided in case it becomes necessary to quickly transport someone to an outside medical care facility.

-

Self-driving electric bus

In April 2018, a self-driving electric bus service went into operation, for the first time in Japan. It is planned to successively replace existing vehicles for movement inside the Fukushima Daiichi Nuclear Power Station premises with self-driving electric buses, which is seen as contributing to more efficient movement and improved vehicle management.

Worker radiation exposure levels

Along with efforts to create a better working environment at the Fukushima Daiichi Nuclear Power Station, measures are being taken to reduce radiation exposure levels.

Worker radiation exposure levels and distribution in December, 2025

-

The average exposure levels in December, 2025 were well below the 1.67mSv level that is the monthly average limit derived from the upper limit of 100 mSv/5 years.

The upper limit for radiation exposure by people engaged in radiation work is 100 mSv/5 years and 50 mSv/year.

While no monthly limit has been set, the five-year amount of 100 mSv when averaged monthly works out to 1.67 mSv/month.

| Levels (mSv) | December 2025 | ||

|---|---|---|---|

| TEPCO employees | Partner company workers | Total | |

| Above 100 | 0 | 0 | 0 |

| Above 75 to 100 | 0 | 0 | 0 |

| Above 50 to 75 | 0 | 0 | 0 |

| Above 20 to 50 | 0 | 0 | 0 |

| Above 10 to 20 | 0 | 0 | 0 |

| Above 5 to 10 | 0 | 10 | 10 |

| Above 1 to 5 | 21 | 339 | 360 |

| 1 or less | 987 | 6909 | 7896 |

| Total | 1008 | 7258 | 8266 |

| Max. (mSv) | 2.83 | 6.34 | 6.34 |

| Avg. (mSv) | 0.08 | 0.19 | 0.18 |

※Note: The above exposure levels and personnel numbers are subject to change, such as in cases when APD values are replaced by monthly dose data measured by integral dosimeters, or reflecting values from workers wearing only an integral dosimeter (e.g., those working only in the seismic isolation building).

Trend in worker monthly exposure levels

“Evaluation of the exposure dose of workers engaged in radiation work at the Fukushima Daiichi Nuclear Power Station” provides data on monthly trends, etc.

See here for detailed information.