TEPCO's Endeavors

- open innovation -

Open Innovation

Enhancing Open Innovation Efforts

The TEPCO Group utilizes revolutionary technologies, services, and ideas in order to create new values and find solutions for issues faced by the company and the society in general.

In particular, we are promoting the use of "open innovation" methods, which allow us to bring in new technologies and ideas from various companies, startups, researchers, research institutes, and other sources around the world in order to find solutions for the issues we cannot solve on our own in a timely fashion.

Here are some of the projects we are undertaking in cooperation with companies, research institutes, and other organizations abroad.

When necessary, we post requests for the information or technologies our Company and its Group need on our online platform called "TEPCO CUUSOO." We are looking forward to any suggestions, ideas, and technology information that could help us tackle various issues.

Open Innovation Project Example

Case 1: Steel Tower Coating Robots

How Steel Tower Coating Robots Were Developed

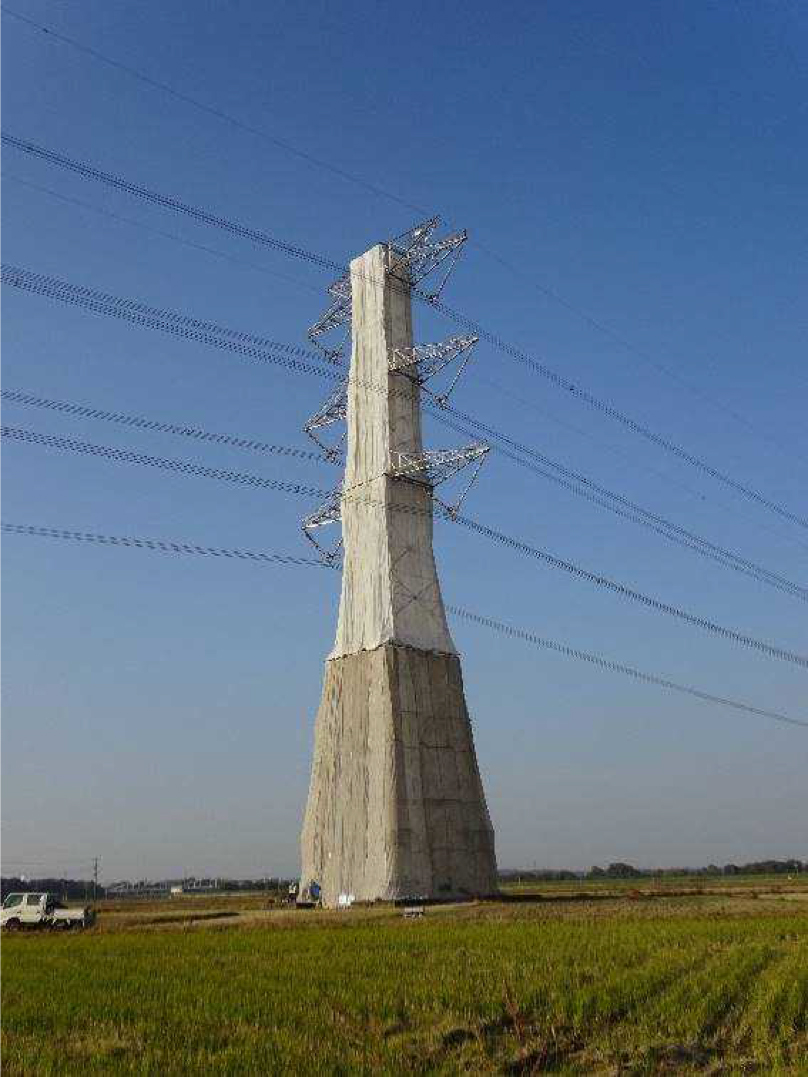

Coating transmission towers is an expensive and labor-intensive process. In addition, the power lines need to be shut down during coating work to protect them from splatters. In order to tackle this issue, TEPCO asked the public to provide technological solutions through the open innovation platform in order to develop innovative steel tower coating technologies that would reduce coating costs and avoid the need to shut down power lines.

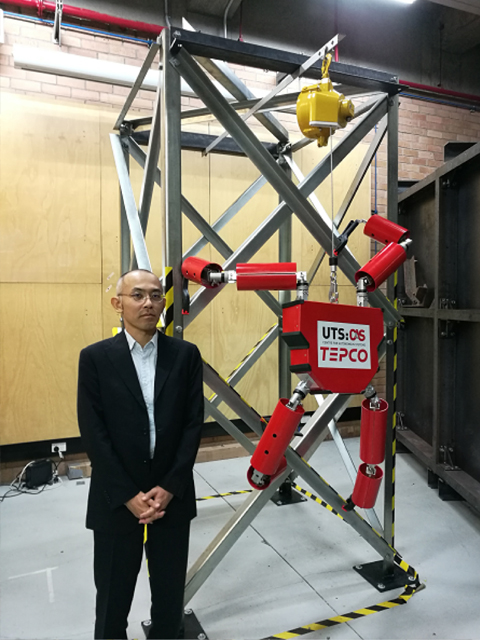

After reviewing the technological proposals, TEPCO started the research process in cooperation with the University of Technology Sydney, which boasts a robot research group called "Centre for Autonomous Systems (CAS)" and specializes in biomimetic robots. Also, many of the machines they have developed have been put to practical use, including the blasting machine and internal arch inspection robot on the Sydney Harbour Bridge.

Main Research Results in Stage 1

1. Determining the Required Specifications of a Steel Tower Coating Robot

We determined the physical dimensions and characteristics, operating environment, gripper safety and adhesion methods, precision, maintenance requirements, and other required specifications.

2. Designing, Selecting, and Conducting Movement Performance Simulations on "ToMBot"

We created three different concept designs for robots capable of climbing up and down the steel tower angle bars. We eventually selected a four-limbed robot concept named "ToMBot" due to its inherent kinematic stability. ToMBot's position is controlled by its three-point support system, which makes it unnecessary for the wrists to be powered during locomotion, thus the three-axis wrist motors can be made more compact and lighter.

Next, we used a numerical and visualization software to check the locomotive capability of the kinematic model and transferred the results to a 3D model that included the device structure and joint angles. We then tested the movement performance again in Gazebo (a 3D simulator).

A section of a steel tower and a mock up model of ToMBot

A section of a steel tower and a mock up model of ToMBot in the experiment room

3. Creating a Gripper Prototype Featuring a Fall Prevention Mechanism

When creating a gripper prototype, we selected a system that enabled the robot to grip various shapes with a single motor. The current version is compatible with L45 to L75 angle bars.

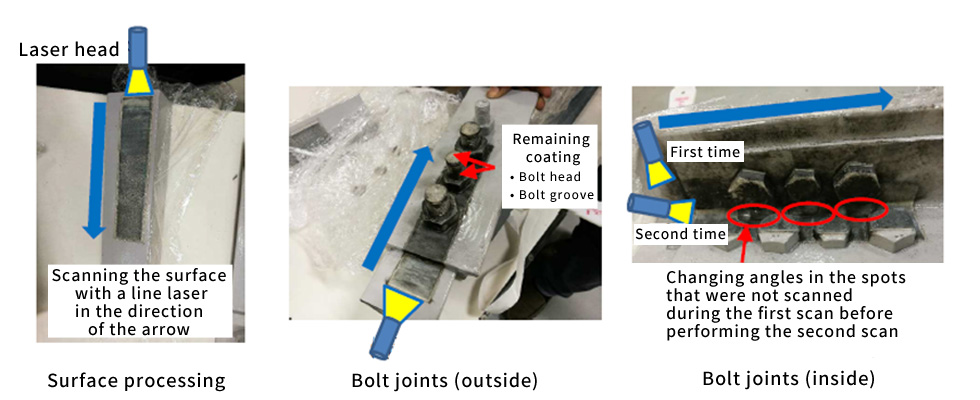

4. Performing Coating Film Peeling Tests with a Laser Surface Scraping Device

We used our test pieces to carry out tests with a laser surface scraping device. We mostly focused on checking conditions of the bolt joints.

In the future, we are planning to select a suitable manufacturer.

The research results in stage 1 confirmed that the technological requirements were fulfilled for the most part. We are going to make the necessary preparations to start stage 2 of our technology development efforts.

Case 2: Electricity Load Forecasting Technology Contest

In order to make sure our electricity supply remains efficient, we forecast the demand for electricity on a daily basis. Our current forecasting system allows us to utilize the know-how we have accumulated over the years and make highly accurate forecasts. However, due to recent advances in data science and forecast technologies, we believed it was necessary to acquire new technologies and expertise. Thus, we decided to organize the "First Electricity Load Forecasting Technology Contest" in order to receive proposals for new methods to forecast electricity demand with a higher degree of accuracy.

We provided the participants with past electricity demand data owned by TEPCO Power Grid, Incorporated, and asked them to devise a method to forecast the demand in one-hour intervals over a span of 24 hours the following day. The participants had to then use their methods to make actual forecasts.

Next, we selected nine most accurate methods and held a final screening session through video presentations to narrow down our selection to six winners.

In this contest, we received more than 100 proposals from domestic and foreign companies, research institutes, and students. Approximately 40% of all the entries came from abroad. As is the case with actual electricity demand forecasts we make at our company, the participants had to forecast the following day's demand within a short period of time. Nevertheless, a lot of the results they produced were highly accurate, which lifted the overall quality of the contest.

Final judging

The Judging Committee met on Thursday, October 19, 2017 to discuss the contents of the presentation videos, after which the rankings were determined.

The head of the Judging Committee, Project Associate Professor Yutaka Matsuo of Tokyo University, commented on the contest, "This contest provided a beneficial overview of the different methods that are possible. If this contest and other similar efforts continue to develop, it may be possible to recruit technical experts who will help us become the firm with the world's most accurate forecasting. In that sense, the contest seems to hold great potential for the future."

In order to ensure an affordable and stable electricity supply, we need to accurately forecast the demand for electricity and operate our facilities efficiently. Due to the diversification of power sources, the circumstances regarding electricity supply and demand are becoming increasingly complex. The TEPCO Group is therefore planning to bring in new technologies and expertise from outside resources in order to actively pursue the goal of improving accuracy.